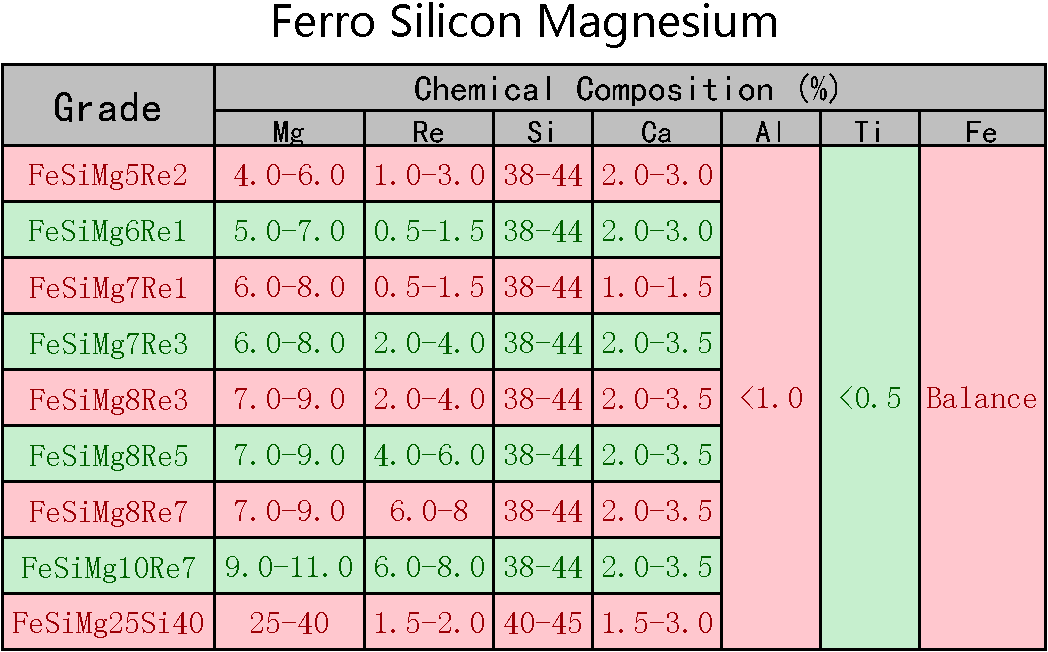

Magnesium content of 4%, 5%, 5.5% is a low magnesium spheroidizing agent, RE is between 1% and 2%, mostly used for medium frequency furnace smelting, low sulfur iron spheroidization. It has the advantage that the spheronization reaction is gentle and the spheroidizing elements are easily absorbed. Magnesium content 6%, 7% is a medium-magnesium series of Nodulizers, used for cupola, electric furnace double smelting, or medium frequency furnace melting pearlite cast as cast nodular cast iron. According to the wall thickness of the castings and the sulfur content of the original molten iron, the appropriate amount of Nodulizer added is determined, the scope of application is wide, and the spheroidizing process is extensive. High-magnesium series balling agent, suitable for cupola smelting, sulfur content 0.06%-0.09% of molten iron, the amount of 1.6% -2.0%. Low aluminum spheroidizing agents are used in castings that are prone to subcutaneous blowhole defects, as well as castings that require aluminum content in molten iron. The pure spherulizing agent produced by Ce and pure La has less pure inclusions in the molten iron after the spheroidizing treatment and the graphite ball is completely rounded. The Nodulizer produced by Nb-based heavy rare earth is suitable for large-section castings to delay spheroidization and prevent bulk graphite. Containing Sb Nodulizer for pearlite ductile iron. Low-silicon spheroidizing agents are suitable for use in foundry plants that use large amounts of recycled charge; nickel-magnesium spheroidizing agents are used for high-nickel austenite ductile iron.