How to use Rare Earth Ferro Silicon Magnesium RE FeSiMg Nodulant ?

In the field of industrial production, the main types of Nodulants have Ferro Silicon Magnesium alloy, Rare Earth Ferro Silicon Magnesium alloy, Calcium alloy (more in Japan), Nickel Magnesium alloy and Pure Magnesium alloy, Rare Earth alloy,etc.These alloy is used most widely in the world is the Rare Earth Ferro Silicon Magnesium alloy, in addition also derived the single light rare earths nodularizer (mainly cerium, lanthanum), single heavy rare earths nodularizer (mainly yttrium), containing barium nodularizer, containing antimony nodularizer, containing bismuth nodularizer, containing copper nodularizer, etc.

The Nodulants is an important material is the production of nodular cast iron, its quality directly affects the quality of the production of nodular cast iron, such as the spheroidization rate, and the size of the graphite ball casting, and cast the tendency of shrinkage, porosity, slag, etc.In the production of ductile iron, only fully understand the role of the various elements in the nodularizer, then according to the requirements of the actual production condition, the casting technology, rational selection and correct use of nodularizer, can guarantee to produce high quality nodular cast iron.

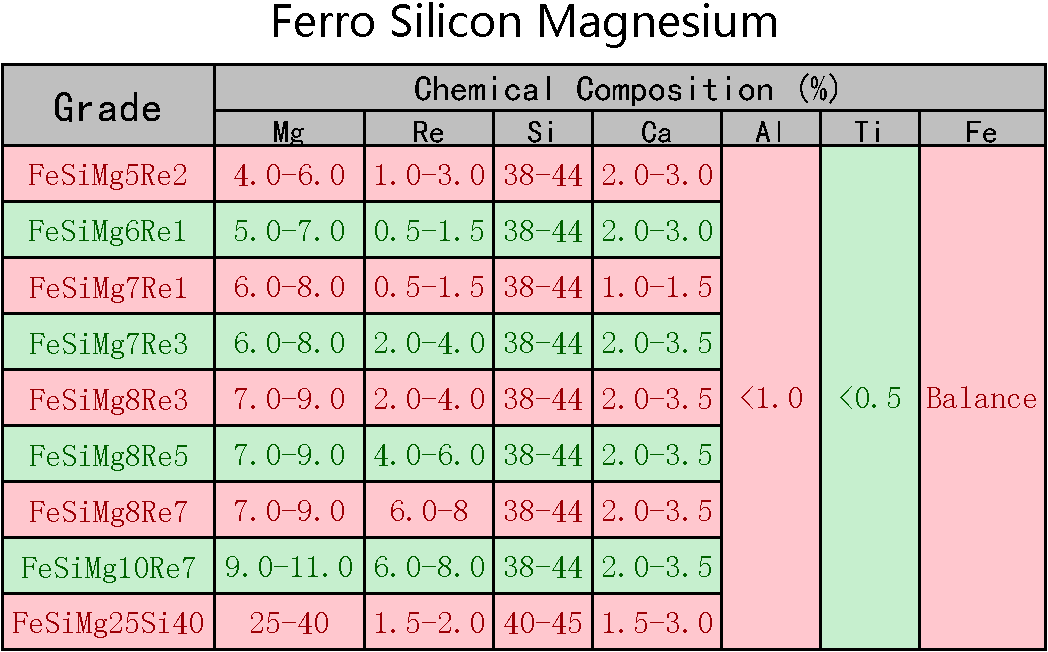

Ferro Silicon Magnesium Alloy

Characteristics

Ferro Silicon Magnesium Alloy uses the advanced smelting craft production the Nodulizer product, the organization is compact, the ingredient is stable, does not have the deflection evenly, the MgO content is low. The spheroidization response is steady, the magnesium absorption rate is high, the anti-decline time is long. After spheroidizing, the stone ball not a strike circle entire, tiny, the tendency is small. Strong spheroidizing ability, stable composition and reaction.

Application

Ferro Silicon Magnesium Alloy used for nodular cast iron, adding hot metal can play a role in spheroidizing, desulfurization and outgassing. Ferro Silicon Alloy can also improve the molten iron purity; generate compound insoluble in water with arsenic, zinc, tin, lead and other low melting point impurity.

Standard

Size: 0.5-6mm; 1-10mm; 1-20mm; 3-25mm; etc.

Packing: outside arrange model the double-decked bagpacking.

The specification, packaging and granular size can be produce according to customer demand.

If you have any questions, Please contacting us.